FILTRATION CONSULTING

“An expert is a man who has made all the mistakes which can be made, in a narrow field”

Niels Bohr

Most mining, refining and processing plants incorporate a number of filtration and separation stages which define process efficiency and economics:

- Clarification or polishing of pregnant liquor by pressure filters, eg in leach circuit

- Dewatering of flotation or precipitation products by vacuum or pressure filters

- Residue removal or tailings dewatering

In Partnership with our clients, GBL DrM does endeavour to

- Maximise OH&S

- Increase production

- Lower costs

- Improve product quality

Consulting Services

- Filter plant audits – Optimise training, process, mechanical and maintenance

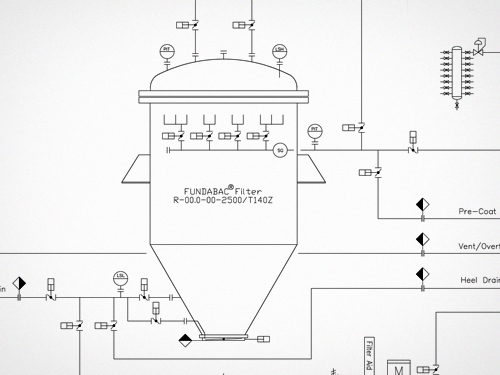

- Filter improvement studies – Vacuum, pressure and clarification Filters

- Filter selection, sizing, specification, design and tender evaluation

- Testwork – Laboratory and on site with our own bench and pilot test rigs

Operation Services

- Regular filter plant assessments

- Preventative maintenance programs

- Operator training & staff education

- Trouble Shooting

Reference list (extract)

- Improvement studies for vacuum belt, drum, disc filters and filter presses

- Bench and pilot scale filter testwork programs for product and tailings

- Selection, sizing and design of vacuum and pressure filters

- Plant audits and filter optimisation studies including training

- Applied R&D and publications

- Bench and pilot scale testwork for product and tailings filtration

- Commissioning and troubleshooting of vacuum and pressure filters